FIVE ORIGIN

OUR COCOA BEANS

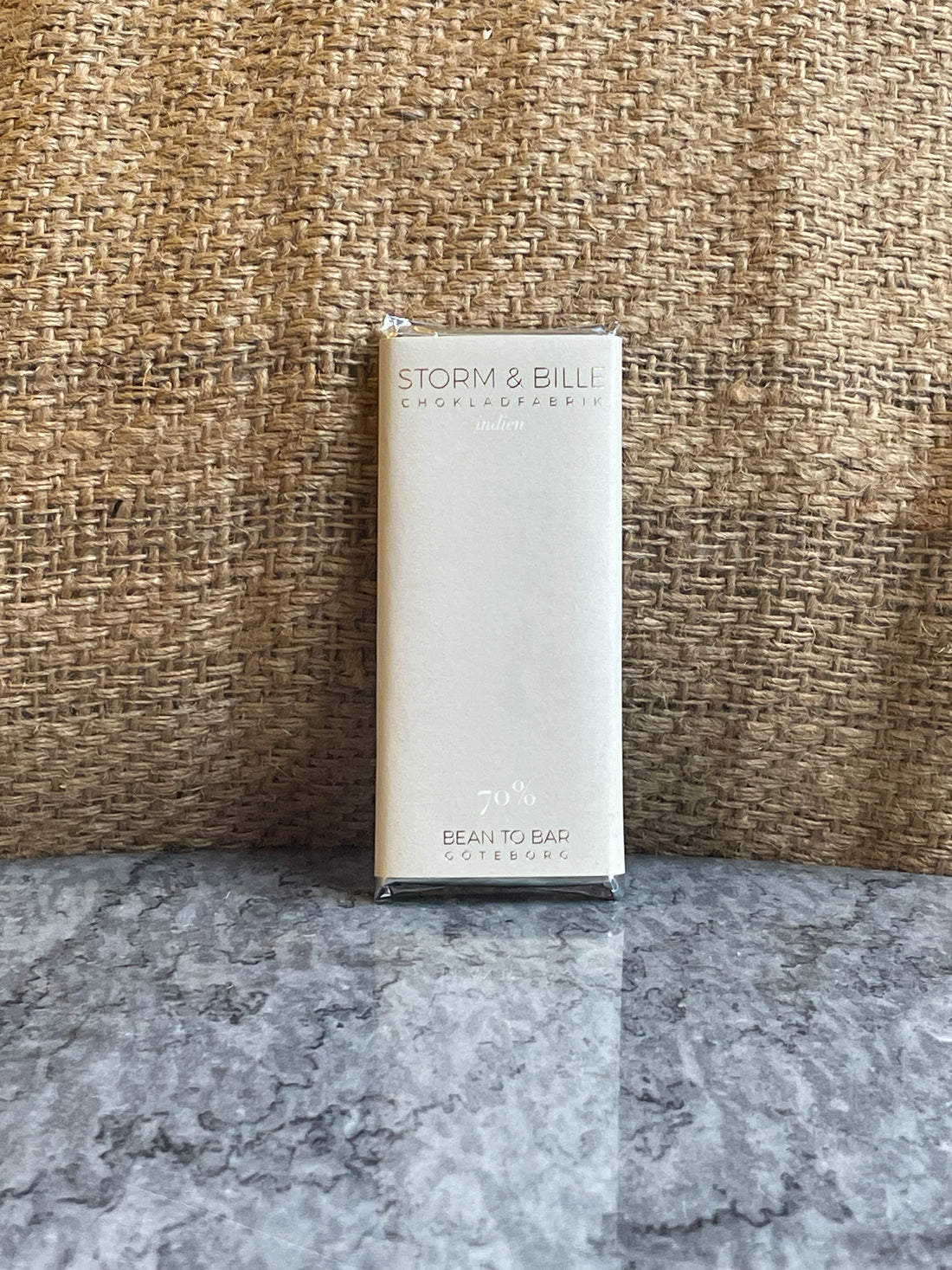

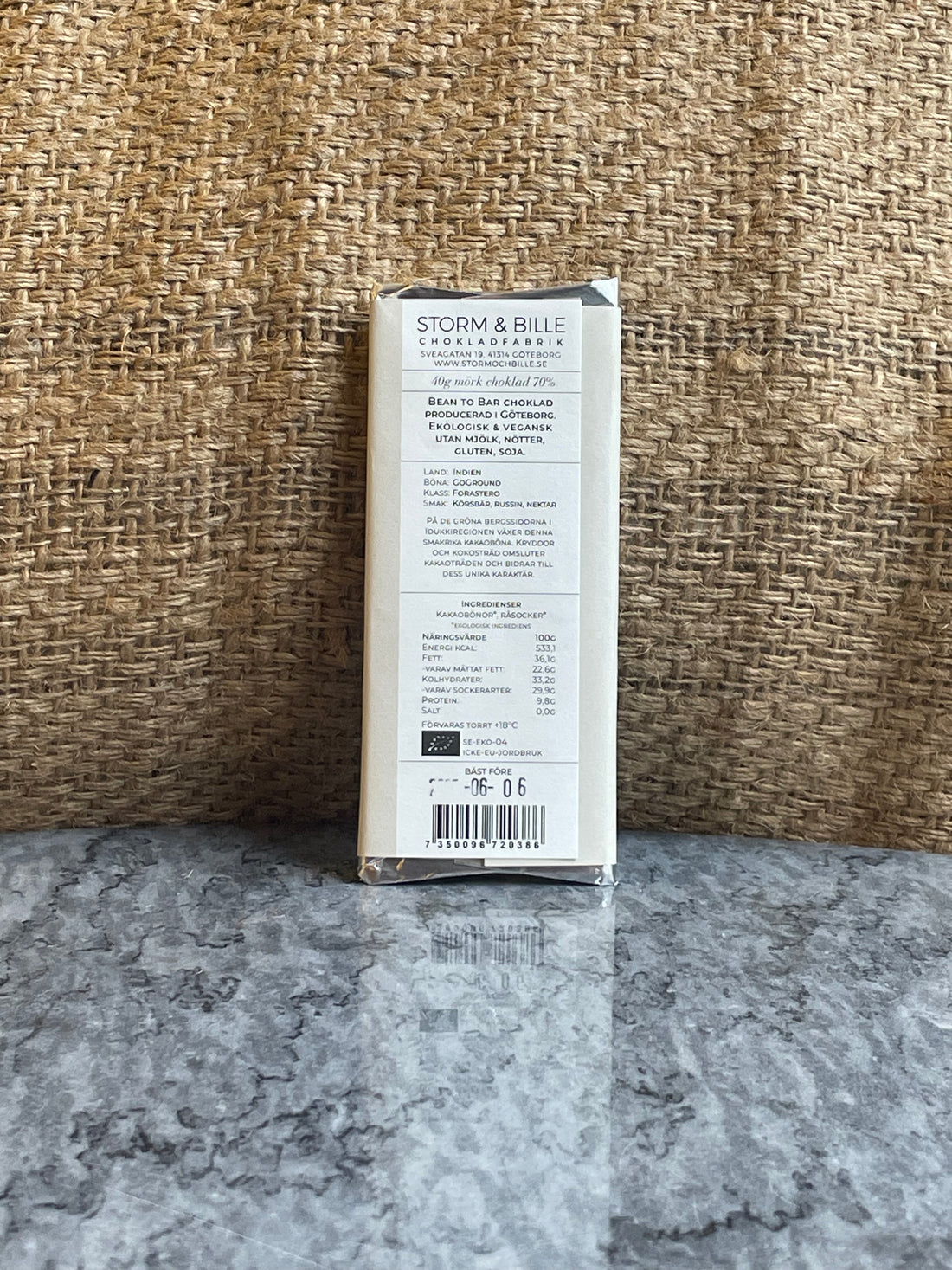

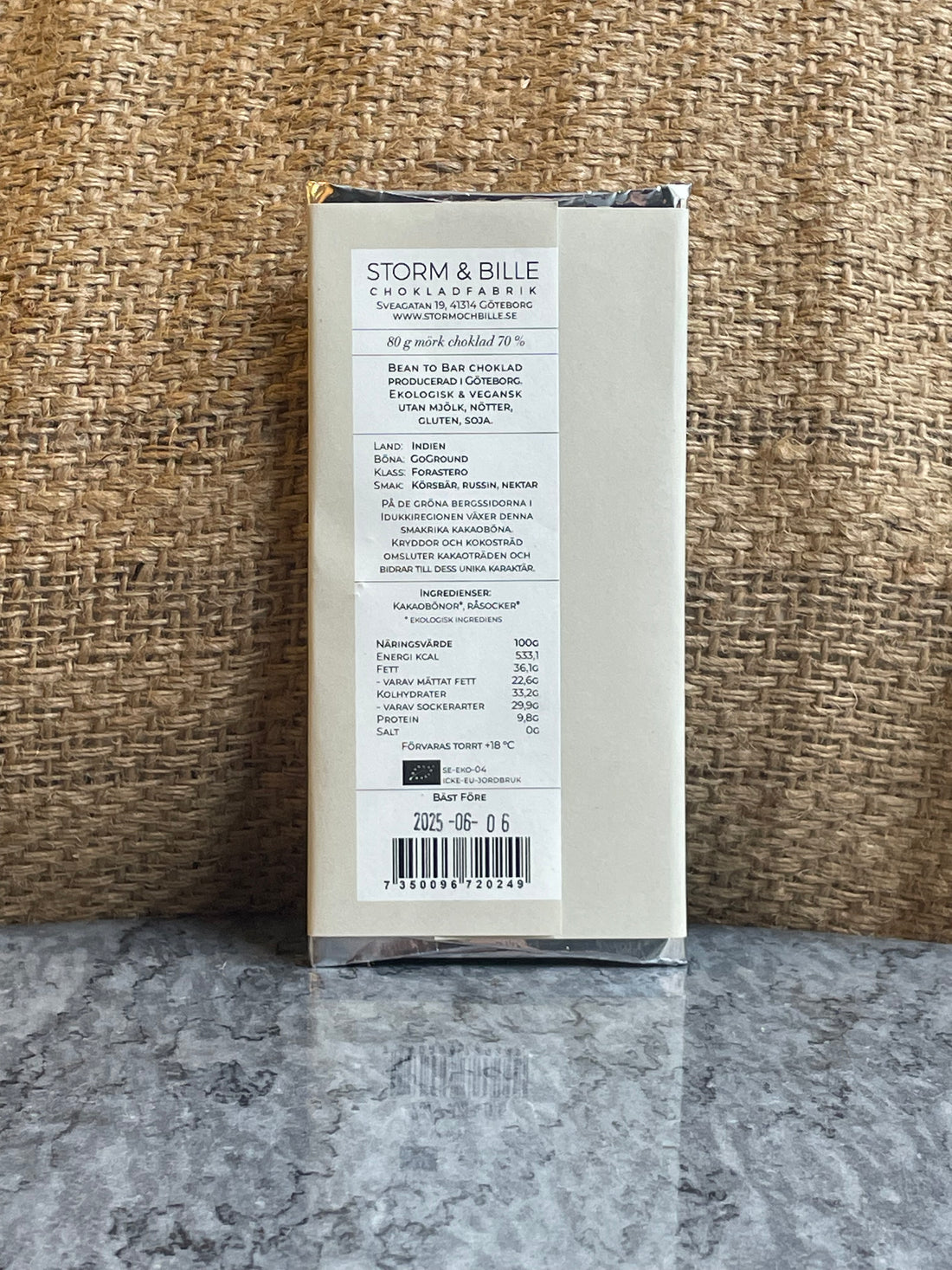

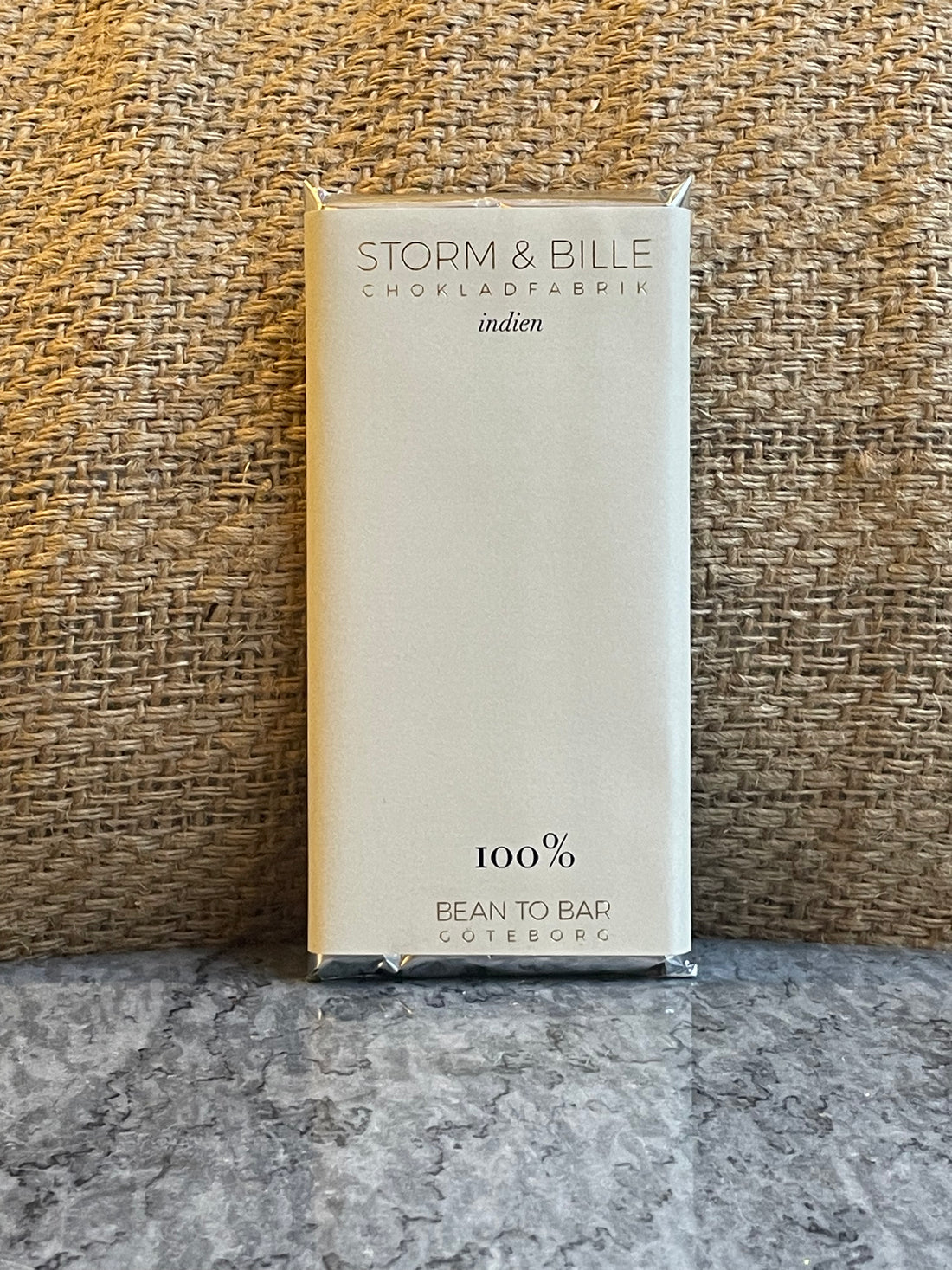

GoGround, India

On the green hillsides of the Idukki region in southern India, we find this tasty cocoa bean. Spices and coconut trees surround the cacao trees and contribute to its unique character. GoGround is run by a young Italian couple who are passionate about contributing to a better life for farmers in the Indian countryside.

Name: GoGround Country: India Classification: Forastero Taste: Cherry, Raisin, Nectar

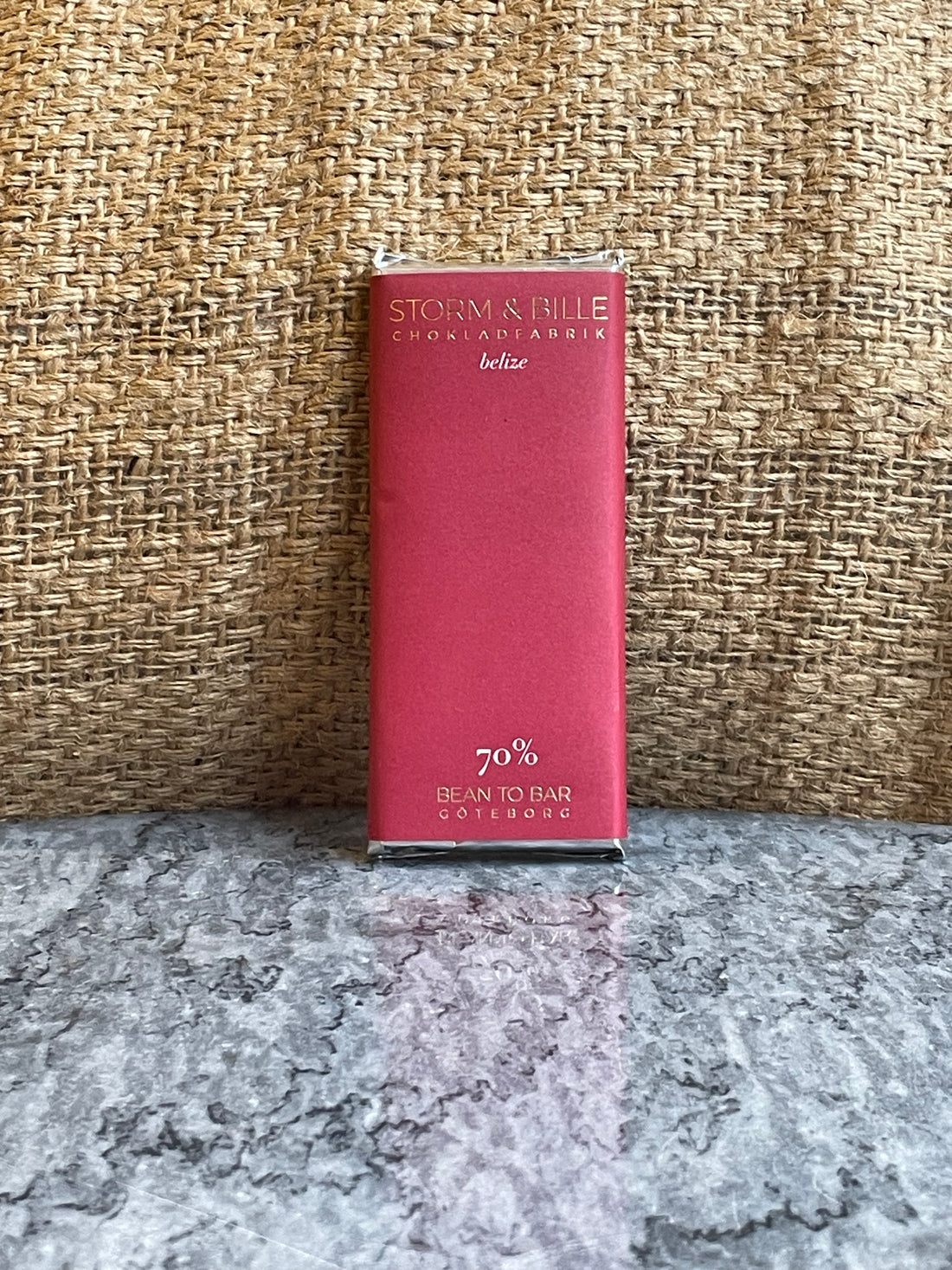

Maya Mountain, Belize

Saõ Tomé & Principe is Africa's second smallest country and was previously the world's largest cocoa producer, it is therefore called the chocolate island. The tropical paradise is located to the west of Gabon and south of Nigeria on the west coast of Africa. The cooperative CECAQ 11 consists of 11 communities from the southern part of Saõ Tomé where just over a third of the members are women. They produce this chocolately flavored Amelodano bean with notes of chasen nut and a musty smokiness.

Name: Cecaq 11 Country: Saõ Tomé Classification: Forastero Taste: Cocoa, cashew, smoky

Semuliki Forest, Uganda

The Mountain of the Moon, or Rwenzori as the mountains are also called, is part of the Virunga National Park on the border between Uganda and Congo. The national park is the oldest in Africa and the area is known for its biodiversity, including a large population of mountain gorillas.

Name: Mountain of the Moon Country: Uganda Classification: Trinitario/Forastero Flavor: Apricot, hazelnut, cream

O´Payo, Nicaragua

O´Payo, with its creaminess and notes of exotic fruits, grows in Waslala near the Bosawa Nature Reserve which is the largest in Central America. In 1997, the area was declared a biosphere reserve by UNESCO.

Name: O´Payo Country: Nicaragua Classification: Trinitario/Criollo Taste: Coffee, kiwi, pineapple

1. Cocoa beans

The cocoa bean comes from a fruit that grows on a tree found around the equator. We take home small test batches around 250-1000g that we test with our lab equipment before we decide to take home larger batches for production. The beans arrive at the factory in 25-60kg sacks.

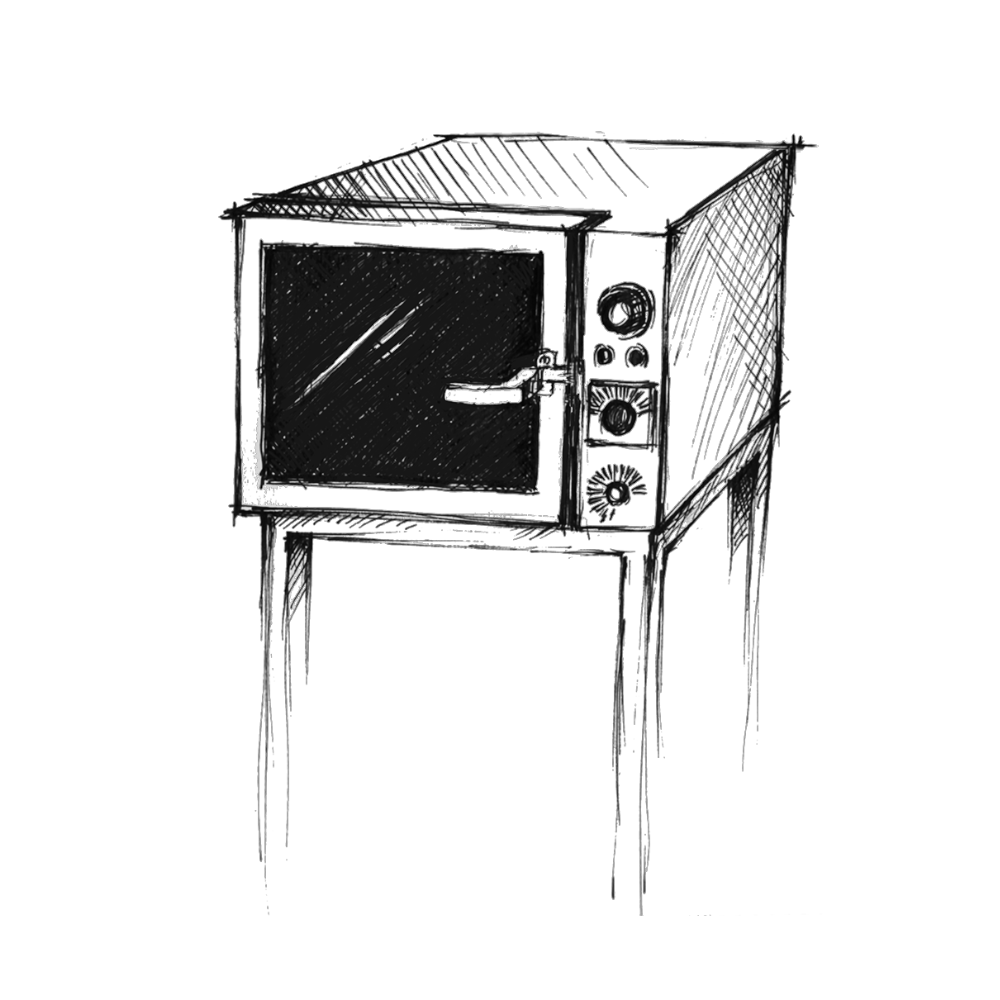

2. Roasting

We hand-sort the best beans for roasting. Finding a good roasting profile for each bean is important to achieve the desired result.

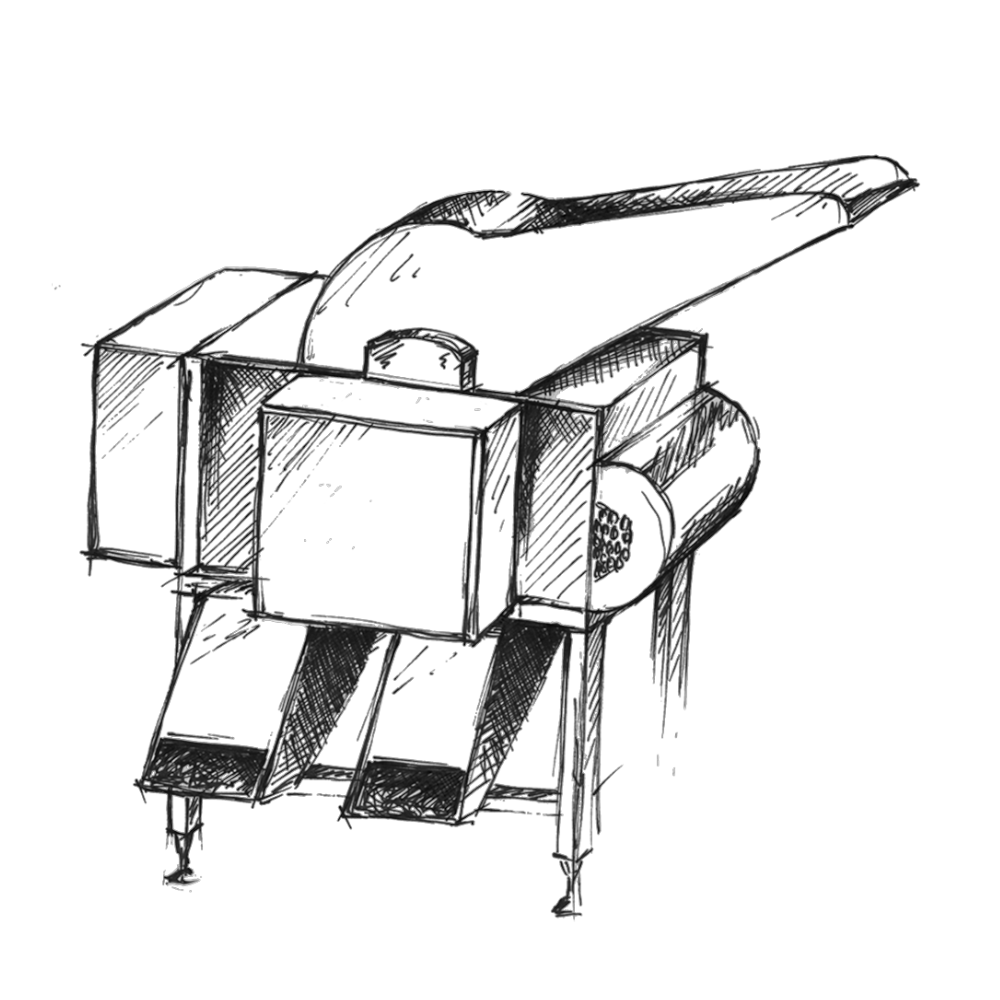

3. Winnowing

We crush and peel the beans with a special machine called a Winnower. At the top of the machine, the beans are crushed, after which a fan blows away the lighter husks into a collection vessel. The heavier cocoa pieces (cocoa nibs) fall out of the machine into a vessel for further production. We use the peels in the collection container to make our chocolate tea.

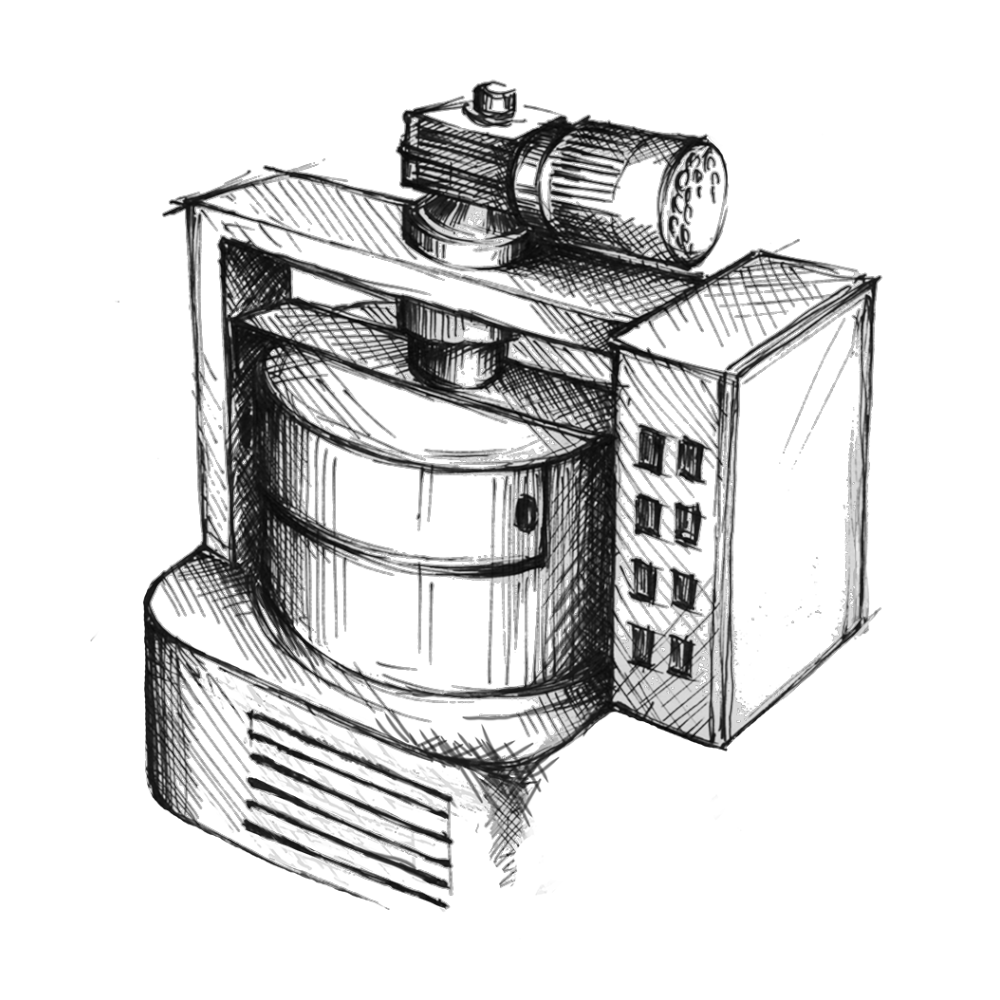

4. Stone grinding

Now it is necessary to reduce the particle size of the chocolate so that it tastes good. Our stone grinder consists of two large granite wheels that roll on a granite slab and over time grind the mass down further. Here the mass is reduced to below 30 microns. This takes 24-72 hours depending on the nature of the bean. We also add raw sugar at this stage. The cocoa bean consists of approx. 50% fiber and 50% butter so at this stage the mass goes from solid to liquid form.

5. Conching

A process where the chocolate is aerated and mixed vigorously, partly to remove unwanted aromas but also to highlight new flavors that are hidden in the chocolate's inner DNA. Depending on the time in our conch, we can create different flavors with the same chocolate.

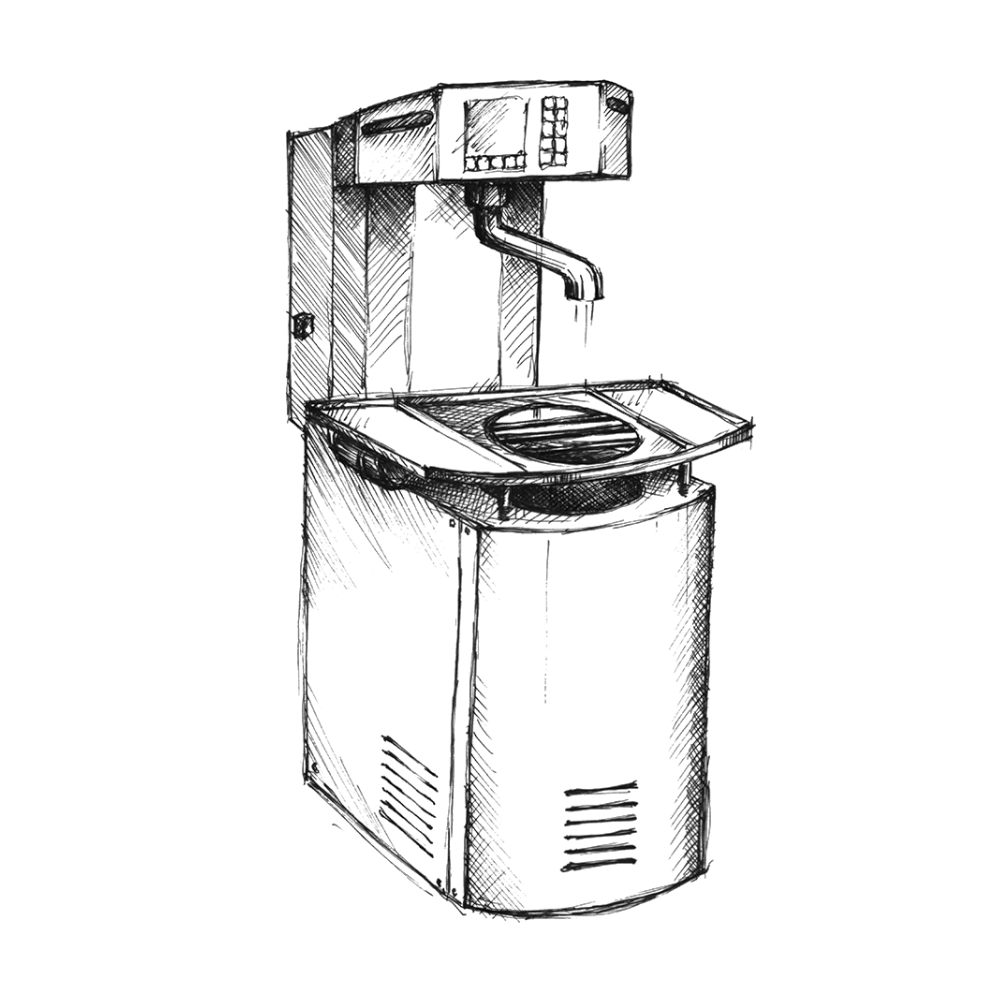

6. Tempering

Tempering - in order for the chocolate not to separate and bloom (turn gray and dull), it must be tempered. This is done by raising/lowering/raising the temperature. From our tempering machine, we dispense the chocolate into cake molds, which are then hand-packaged with both inner and outer packaging.